CANDU and Heavy Water Moderated Reactors

The CANDU reactor was designed by Atomic Energy Canada Limited (AECL) as an alternative to other reactor designs which use slightly enriched uranium (2-5% U-235). The CANDU allows more local input in nations that do not have the capability to cast a pressure vessel. The CANDU fuel contains pellets of uranium dioxide with natural uranium (0.7% U-235). As a result, the CANDU is cheaper to fuel, and can theoretically give higher lifetime capacity factors. Details on why the CANDU design was developed and engineering specifics can be found at Dr. Jeremy Whitlock's The Canadian Nuclear FAQ site.

The CANDU design consists of a horizontal calandria (Vessel) which has tubes for the fuel rods and cooling water (heavy water). Around these tubes is heavy water, which acts as the moderator to slow down the neutrons. Heavy water consists of 2 atoms of deuterium (a non-radioactive isotope of hydrogen) and 1 atom of oxygen. Deuterium atoms represent about 1.5% of hydrogen found in nature. Deuterium is much more efficient as a moderator than light water, thus allowing the use of natural uranium as a fuel. Special processing plants, e.g. at the Bruce facility near Tiverton, Ontario, are used to separate heavy water from natural water. The deuterium separation is an added initial capital cost which, over the plant lifetime, is offset by the lower natural uranium fuel costs.

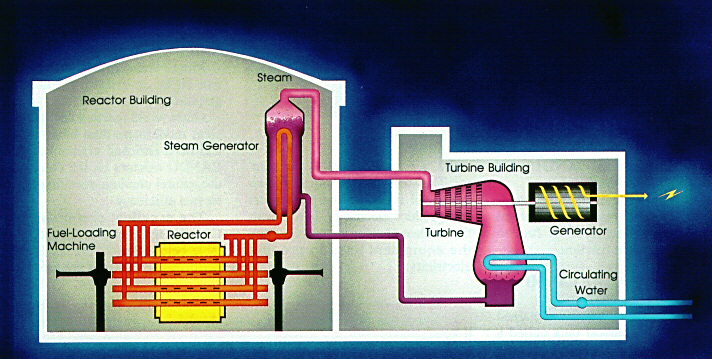

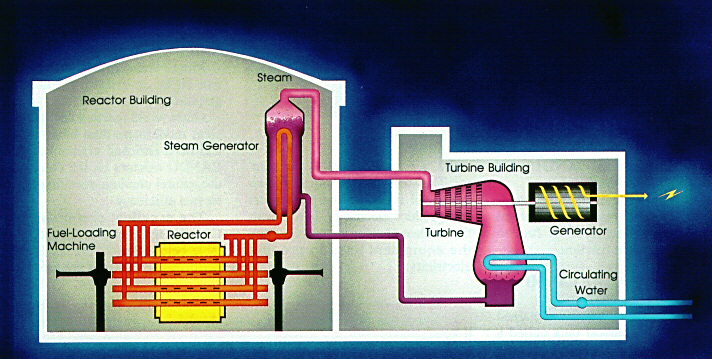

As in the case of the pressurized water reactor, reactor cooling pumps circulate heavy water through the reactor then to the steam generators in a closed loop. The moderator heavy water system has a separate heat exchanger with circulation system for cooling the moderator.

|

| Courtesy Canadian Nuclear Association |

The CANDU reactor's cooling water tubes are pressurized to 1525 pounds per square inch, lower than pressurized water designs. The heavy water in the moderator system is normally not highly pressurized. The reactor, refueling machine, and fuel designs are illustrated and discussed under CANDU reactor and fuel design. Additional information is provided under CANDU Reactor/Fuel/Shutdown System Specifics.

These reactors have considerable redundancy in secondary system equipment so that longer operating cycles are possible. Cycle times have even reached 894 days (Pickering 7 in 1994). Because of this, the CANDU designed reactors typically have the highest world capacity factors. On the other hand, fuel burnup in a CANDU is only 6500 to 7500 MWD per metric ton uranium (MTU). This compares with 33000 to 50000 MWD/MTU obtained by many PWR and BWR reactors.

The CANDU design multi-unit stations use a vacuum building as a special containment protection feature. The Vacuum Building design is discussed under Containment Pressure Control Systems. In the Pickering plant photograph, the Vacuum Building is the large cylindrical building located behind the 8 reactors.

CANDU reactors differ from many other designs in that there is more extensive use of computer-based control systems including for reactor protection.

CANDU power plant sites have between 1 and 8 reactors per site. The Pickering facility east of Toronto on Lake Ontario and the Bruce facility northwest of Toronto each have 8 reactors per site. Nominal electrical output is 600 MWe per unit.. CANDU reactors are used to supply power in Ontario, Quebec, and New Brunswick by 3 utilities:

Photo courtesy New Brunswick Power

AECL, the manufacturer of CANDU reactors, has also provided these reactors to governments/utilities in Argentina, India, Korea, Pakistan, and Romania. For more information, CANTEACH is a non-commercial project dedicated to collecting educational and training materials related to CANDU technology. The project is administered by CANDU Owners Group (COG). Materials are posted on CANTEACH public web site and can be used by anyone to prepare their own presentations / course notes. Canadian utilities and Universities all donate their materials to the site.

Copyright © 1996-2006. The Virtual Nuclear Tourist. All rights reserved. Revised: December 31, 2005.