- Vertical U tube

- Horizontal

- Once through

Steam Generators and Steam Separators

Steam Generators

The function of the steam generator is to transfer the heat from the reactor cooling system to the secondary side of the tubes which contain feedwater. As the feedwater passes the tube, it picks up heat and eventually gets converted to steam. The steam generators may also contain a steam separation region, described below.

There are three types of steam generators:

|

|

| Graphic courtesy EPRI |

Most American, Canadian, Japanese, French, and German PWR suppliers use the vertical U-tube design with inverted tubes. Babcock & Wilcox uses the once-through design. This design is a straight through tube with a vertical steam generator and vertical tubes. The Russian VVER reactor designs use horizontal steam generators, which have the tubes mounted horizontally. The horizontal design has proven to be less susceptible to degradation than the vertical U-tube design.

| Vertical Steam Generator (Click to expand) | |

|

The vertical steam generators generally have a feedwater ring supply header on the outer edge of the steam generator. The water is directed downward and flows along a wrapper sheet then is directed upwards to flow along the steam generator tubes where the water picks up heat, increasing in temperature until boiling occurs and the water is converted to steam. In the upper part of the steam generator is a moisture separator region which forces the steam-water mixture through channels which allow steam to pass, but not water. A vane arrangement in these steam generators also force a swirling action that enhances the steam-water separation. The water supplied to the steam generators must be very pure, free of particles, and chemicals. In the boiling environment of the steam generator these chemicals can concentrate resulting in undesired corrosion. The Electric Power Research Institute (EPRI) is a research organization funded by many U.S. and some electric utilities. EPRI has conducted extensive research on cause of tube degradation in steam generators. EPRI's programs are summarized in their Steam Generator Progress Report, where extensive information about the degradation mechanisms and problems noted is reported. (Unfortunately this document is no longer available on the internet). |

| Courtesy Westinghouse | |

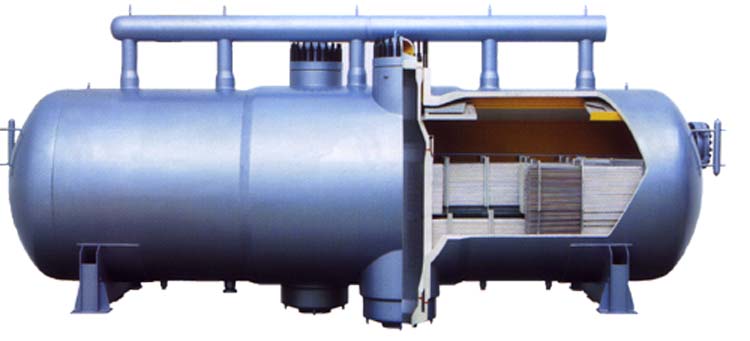

| Horizontal Steam Generator | |

| The horizontal steam generators have horizontal tubes as shown to the right. Reactor coolant flows through the tubes. Feedwater is supplied outside the tubes and is converted to steam that flows up into the header. |  |

| Courtesy CEZ |

During refueling outages, the steam generator tubes are inspected for degradation and thinning using a non-destructive examination method known as eddy current testing. Probes as the one shown below are routed through the tubes and signals from the sensor are evaluated using a computer. The probes are used to find defects in the tubing material. If defects are found the tube may be plugged or have a sleeve installed to strengthen the tube.

|

|

| Graphic courtesy Westinghouse Canada |

The function of the steam separators is to remove the water from the steam. This is done to ensure that the steam impinging on the turbine blades causes minimal erosion. The blades are large and steam laden with water can cause severe erosion and wear of the blading. So also can the presence of chemicals, e.g. silica, in the water that is converted to steam.

|

Usually the steam separator may be a separate component when horizontal steam generators are used. Examples are this are those used in the CANDU and VVER designs. It should be noted that steam separation is accomplished internally to the boiling water reactor, as illustrated below. Please click to stop the graphics loading if you consider the time excessive. This diagram illustrates the advanced General Electric Boiling Water Reactor design. Key areas to note relative to the steam separator discussion are:

|

||||||

| Graphic courtesy GE Nuclear |

Copyright © 1996-2004. Joseph Gonyeau, P.E.. The Virtual Nuclear Tourist. All rights reserved. Revised: December 4, 2001.